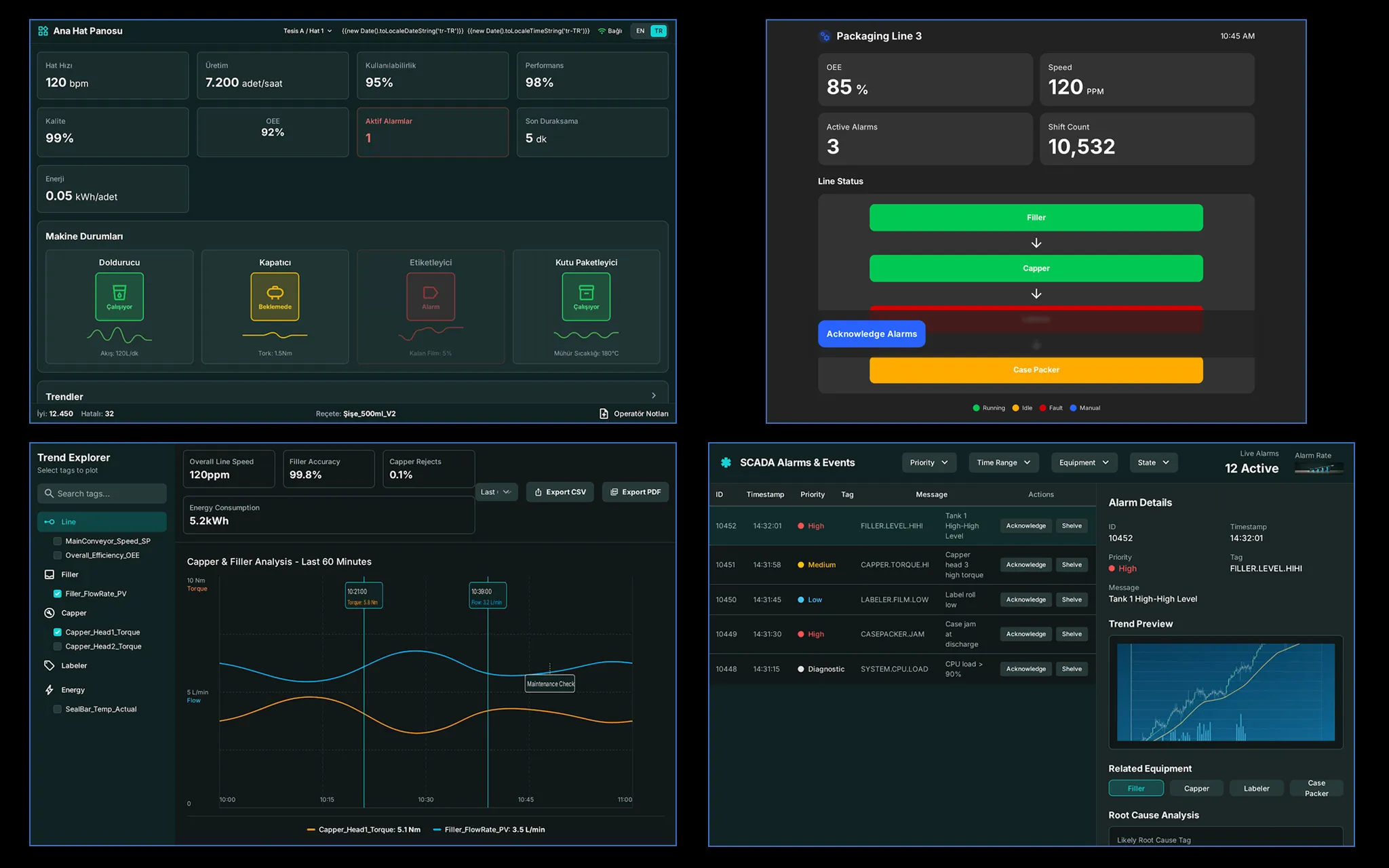

Our SCADA solution unifies production, quality, and energy KPIs on one screen. Operators get real-time visibility, engineers gain analytics, and management receives trustworthy reports. UI design follows ISA-101 (clarity/hierarchy) and alarm philosophy aligns with ISA-18.2.

Scope

- Data & Integration: PLC/OT tag mapping (Siemens, Rockwell, Omron, Beckhoff…), Modbus / Profinet / EtherNet/IP, meters & sensors.

- Screen Design: Line schematic (Filler → Capper → Labeler → Case Packer), KPI ribbon (Line Speed, OEE, Active Alarms, Last Downtime, Energy/Unit), status colors, state timeline.

- Alarms & Events: Priorities, acknowledge/shelve, root-cause tagging, alarm-rate sparkline.

- Trends / Historian: Multi-axis trends (flow, valve timing, cap torque, seal temperature, conveyor speed), archive & export.

- Recipe & Changeover: Guided format changes for speed, torque and temperature profiles.

- Reporting: Shift summary, reject causes, Energy/Unit and OEE reports (PDF/CSV).

- Security: RBAC, audit logs, encrypted tunnel/VPN.

Portfolio Screens

- Main Line Dashboard: KPI cards + line flow + state timeline.

- Alarms & Events: Prioritized list, detail panel, related equipment & mini trend.

- Trend Explorer: Multi-pen charts, cursors/annotations, tag search, export.

- Mobile Summary: OEE, speed, active alarms, compact line schematic (touch-first).

Benefits

- Scenario tests and changeover guidance without stopping production.

- Fast visibility of downtimes and bottlenecks; action on root causes.

- Standardized screens and data integrity for sustainable operations.

- A shared performance language for operations, maintenance, and management.

- Data model and UI ready to work with digital-twin projects.

Project Summary

- Line Type: Liquid filling + capping + labeling (FMCG cleaning products example)

- Our Role: SCADA architecture, UI design, alarm philosophy, historian & reporting, PLC/OT integration

- Technology: WinCC / Ignition / FactoryTalk View or a lightweight stack (Node-RED + InfluxDB + Grafana) — vendor-agnostic